Introduction

As defined in ISO 26262-3 clause 6.4.2.2 the hazards shall be determined systematically based on possible malfunctioning behaviour of the item.

These hazards are essentially vehicle level hazards which in combination with operational situations give exact hazardous event that will be the assessed within risk assessment procedure.

As defined in ISO 26262-3 HAZOP is suitable to support hazard identification at the item level and then it can be supported by brainstorming, checklists, quality history, and field studies to get to the vehicle level effects and hazards (VLH).

A VLH is defined as per the ISO 26262 as being a potential source of harm, and appears in the event chain as follows:

With the following definitions:

| 1 | Item Malfunction | Failure or unintended behaviour of an item with respect to its design intent | ISO 26262 |

|---|---|---|---|

| 2 | System Failure | System level functional failure leading to a VLH | Dictionary |

| 3 | Vehicle Level Hazard | Potential source of harm caused by an Item Malfunction | ISO 26262 |

| 4 | Hazardous Event | Combination of a hazard and an Operation Situation | ISO 26262 |

| 5 | Incident/Accident | Undesirable, incidental, and unplanned event directly causing unintentional injury or harm | Dictionary |

| 6 | Harm | Physical injury or damage to the health of persons | ISO 26262 |

Examples relating to the above definition are mentioned in the chart below:

| No. | Item Malfunction | System Failure | Vehicle Level Hazard | Hazardous Event | Incident/Accident | Harm |

|---|---|---|---|---|---|---|

| 1 | Brake pedal sensor malfunction | No braking demand detection | Loss of braking | Happens at a crossing | Crash with coming car | Crash injuries |

| 2 | Battery voltage sensor malfunction | Overcharge | Thermal incident | any situation | Vehicle fire | Burns, intoxication |

| 3 | Front light command malfunction | No illumination demand detection | Loss of forward illumination | at night on an unlit road | Crash onto a tree | Crash injuries |

This post references the typical identified VLHs that can harm directly vehicle occupants and other road traffic participants including pedestrians and cyclists.

A VLH is a direct source of harm inducing a direct exposure to the:

- vehicle occupants;

- road traffic participants;

- pedestrians;

- cyclists.

The VLHs shall be defined in terms of the conditions or behavior that can be observed at the vehicle level so basically they can be divided into 2 main groups:

- VLHs from the loss of the vehicle control while in motion (motion-related)

- VLHs that are not related to the loss of the motion control (non motion-related)

Vehicle Level Hazards

HAZOP

Hazard identification can be accomplished through various hazard analysis techniques. The hazards shall be determined systematically by using adequate techniques. Regarding the existing methodologies and techniques for the hazards analysis it is considered to do hazard analysis through HAZOP methodology described in IEC 61882. HAZOP is an exploratory type of analysis where applicable guide words are applied to each of the functions of an item to postulate malfunctioning behaviors. HAZOP facilitates a structured and systematic examination of the operation of the item within the vehicle. It may be used to identify and evaluate malfunctioning behaviors of an item that could lead to hazards that create the potential for harm to the occupants of the subject vehicle, to other vehicles and their occupants, or other persons at risk such as pedestrians, pedal cyclists in the vicinity of the subject vehicle or maintenance personnel.

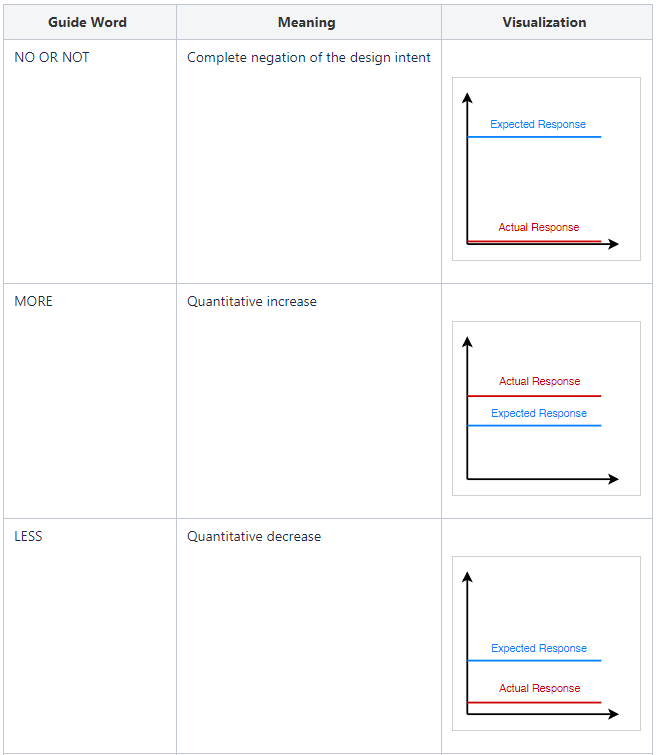

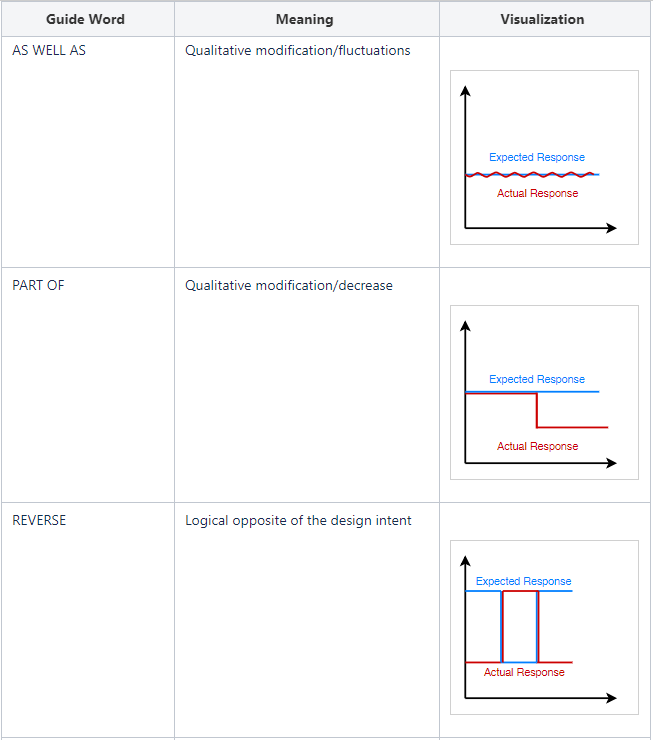

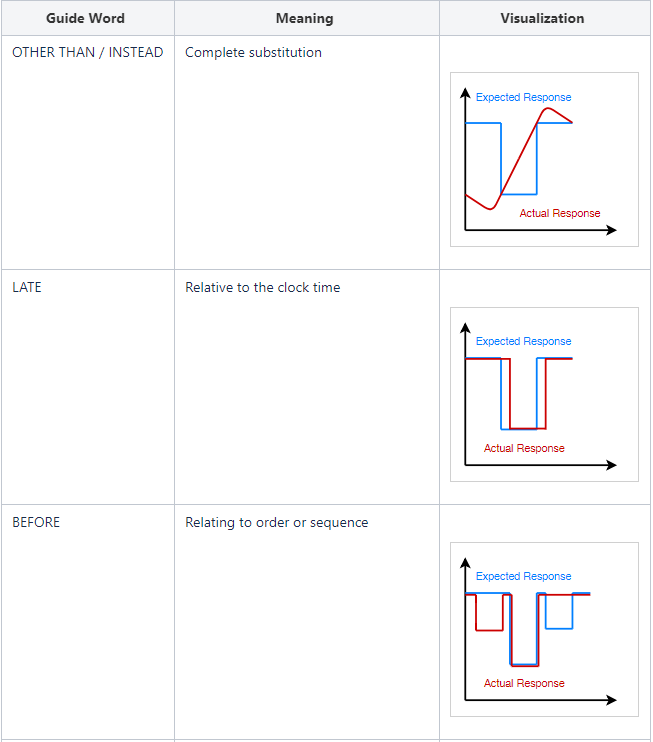

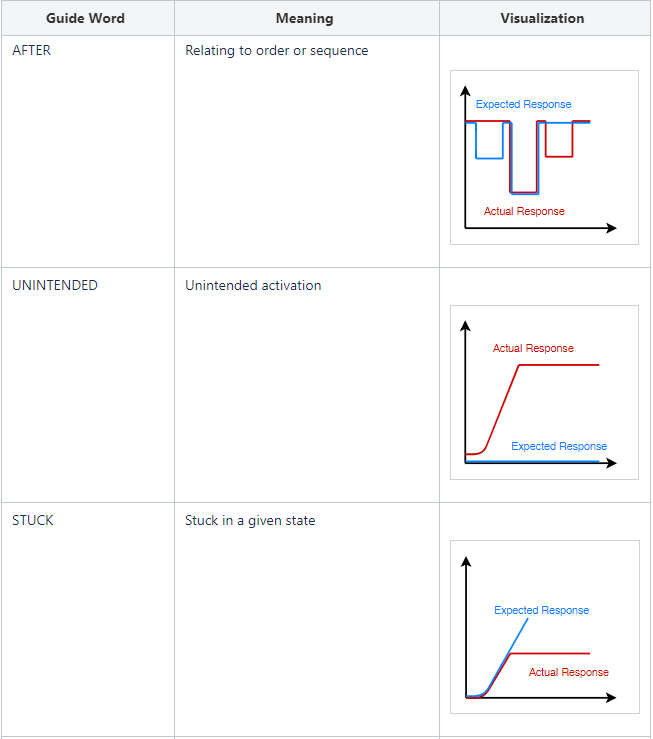

Within HAZOP the analyst assumes there are functions defined during item definition phase and in order to identify deviations applies (systematically) a set of Guide Words to each function. The Guide words are chosen based on idea they shall be appropriate to the study and neither too specific (limiting ideas and discussion) nor too general (allowing loss of focus). As an example the following list of the guide words might be used.

Motion-related Vehicle Level Hazards

The 6 degrees of motion freedom of a solid body are the following:

- Longitudinal

- Lateral

- Vertical

- Yaw

- Pitch

- Roll

All of these degrees of freedom shall be taken into account while identifying VLHs. The VLHs identified can be represented as in the following table

| No. | Guide word | Hazard description (ACCELERATION) | Hazard description (BRAKING) | Hazard description (STEERING) |

| 0 | NOT | No acceleration | No braking | No yaw angle correction |

| 1 | MORE | Excessive acceleration | Excessive braking | Excessive yaw angle correction |

| 2 | LESS | Insufficient acceleration | Insufficient braking | Insufficient yaw angle correction |

| 3 | AS WELL AS | Fluctuations in acceleration | Fluctuations in braking | Fluctuations in yaw angle |

| 4 | REVERSE | Braking instead | Accelerating instead | Opposite yaw angle correction |

| 5 | EARLY | Provide acceleration before required | Provide braking before required | Yaw angle correction provided before required |

| 6 | LATE | Provide acceleration after required | Provide braking after required | Yaw angle correction provided after required |

| 7 | UNINTENDED | Unintended acceleration | Unintended braking | Unintended yaw angle correction |

Non Motion-related Vehicle Level Hazards

| No. | Vehicle Level Hazard | Description |

| 0 | Pressure burst | Critical pressure increase that may lead to pedestrians/cyclists/other drivers hitting (by the vehicle parts) harm. May lead to hazardous events due to release of potential energy – burst; – flying parts; – pressure waves. |

| 1 | Parts disconnection | Disconnection of pats of the vehicle that may lead to pedestrians/cyclists/other drivers hitting harm In case of disconnection inside the cabin may lead to the vehicle occupants hitting harm |

| 2 | Thermal incident | Heating of vehicle parts due to radiated energy, convective energy, conducted energy transmission to that parts. Different from electrical heating related to the Joule effect. May lead to burns harm. May lead to hazardous event – explosion due to release of thermal energy |

| 3 | Toxic gases release | Release of a toxic compound that can be inhaled or touched by the customer. May lead to viscera harm |

| 4 | Irritant release | Release of irritants out of containers. May lead to chemical burns harm |

| 5 | Electrical energizing | Electrical energizing of the vehicle parts that may lead to electrical shock and electrical burns harm |

| 6 | Electrical heating | Electrical heating hazard that may lead to burns harm. May lead to hazardous event – explosion due to release of thermal energy |

| 7 | Electrical arcing | Arcing due to an electrical discharge through the air |

VLH Nomenclature

The following nomenclature (scheme) might be used to classify hazards with the keys.

| VLH | – | Symbol 1 | M | Symbol 3 | – | number |

1st sequence of letters:

VLH: Vehicle Level Hazard

2nd sequence of letters:

Symbol 1:

- F: forward motion;

- R: reverse motion;

- Y: yaw motion;

- S: standstill;

- N: non-motion related.

Symbol 3:

- For Motion related hazards:

- A: Accelerating

- B: Braking

- X: not applicable

- For NON-Motion related hazards:

- M: mechanical hazard;

- E: electrical hazard;

- T: thermal hazard;

- C: chemical hazard;

Thank you, this was really helpful.